| DATE | : – |

|---|---|

| WRITER | : – |

| PUBLISHER | : VAT Vacuum Valves |

VAT’s first solar array – on the rooftop of the manufacturing site in Haag, Switzerland – was completed in 2013 and has been generating electricity ever since.

VAT’s commitment to significantly reduce CO2 emissions encompasses all VAT sites around the world – particularly the company’s administrative and production operations in Switzerland and Malaysia where most of the CO2 emissions are generated. In addition to switching to renewable electricity with the installation of rooftop solar panel arrays, the company is also looking to further reduce emissions by finding ways to use energy more efficiently.

“As a company, VAT pledges to be ‘part of the solution’ and is committed to successively reducing its overall CO2 footprint to zero emissions,” adds Heinz Märkli, VAT Environmental Program Manager.

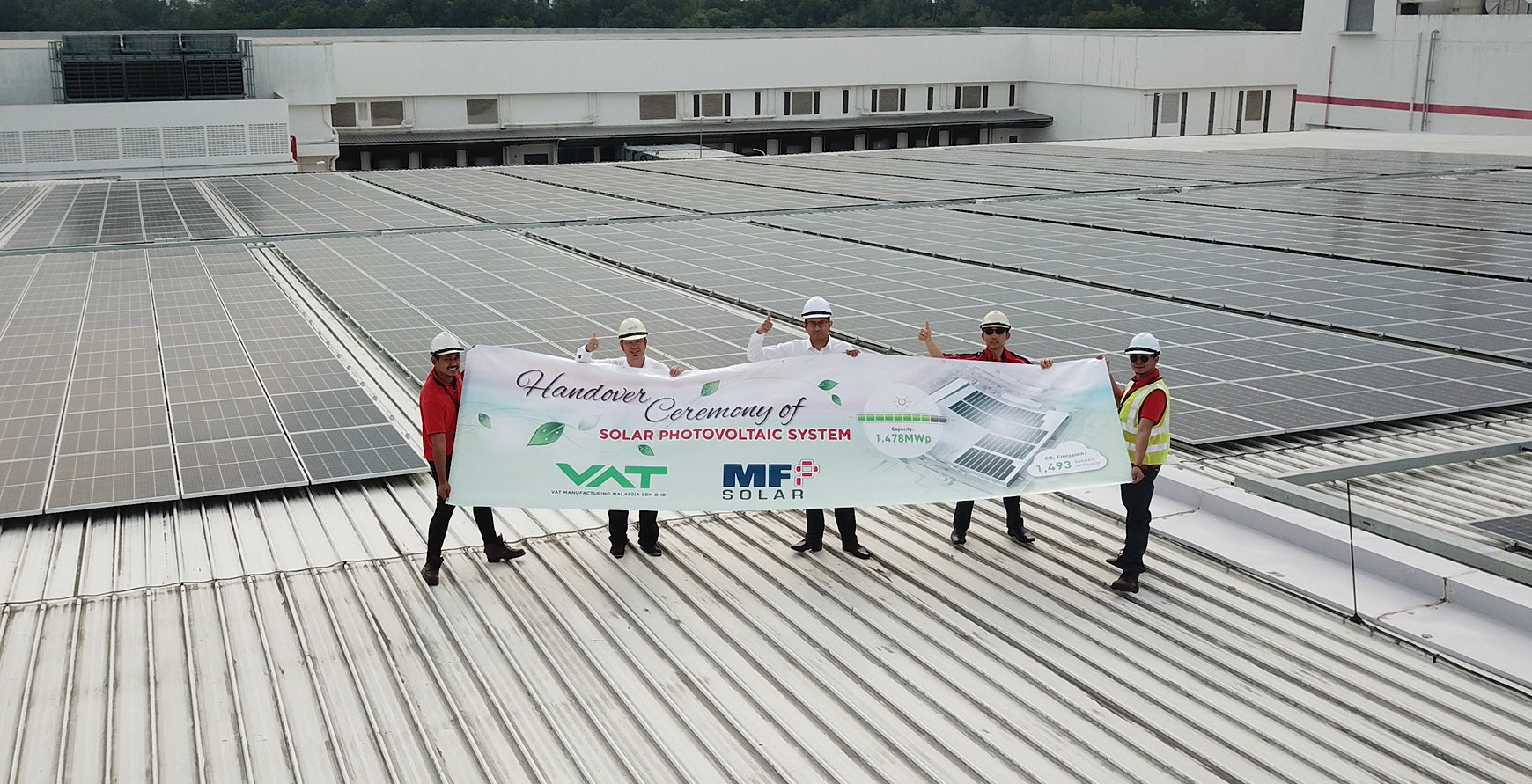

Malaysia Goes First

The photovoltaic system installed on the roof of the VAT manufacturing facility in Penang, Malaysia generates an annual output of 1770 MWh. The resulting energy output is used for facility lighting, powering production systems and other infrastructure. The annual CO2 emission reduction is estimated at 1,334 tons.

Comprehensive environmental effort

Heinz Märkli notes the many steps needed to reach the goal of generating 15 GWh of sustainably sourced electricity to cover the annual energy needs of the Haag, Switzerland headquarters, “The environmental & sustainability management programs at all VAT production sites encompass strict “green” guidelines for any new construction – including high-level insulation, use of ‘smart window’ technology, LED lighting, ground water heat exchangers for machine cooling and comprehensive recycling of packaging – such as the introduction of returnable packaging to further save energy.”

As part of the company’s environmental and sustainability policies, VAT follows the Responsible Business Alliance (RBA) code of conduct and has implemented a number of environmental protection and sustainability guidelines, along with membership in the Economic Energy Agency, a Swiss organization dedicated to helping corporations reduce CO2 emissions and optimize energy efficiency efforts.

Ensuring environmental relevance

In addition, VAT carries out an audit of the company’s energy consumption and sustainability programs every two years to gauge their environmental relevance.

“Our goal to use 100% renewable energy in our manufacturing operations by 2030 is based on sound business reasons,” adds Heinz Märkli. “These measures are expected to lower operating costs and add resilience to our energy supply around the world.”